Industrial Automation & Sensors Blog

Reliability, Accuracy are Paramount for Position Sensor Suppliers

by Andre' Girard, with Jared Weiner | 08/03/2018

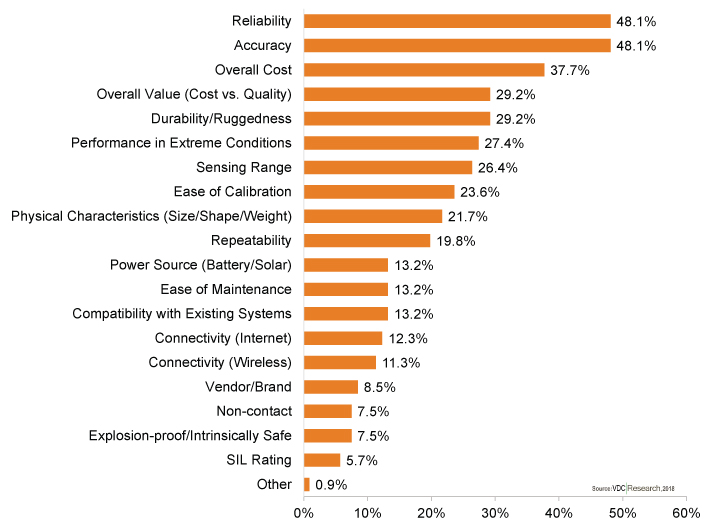

Among the most insightful questions asked within VDC’s annual surveys targeting engineers and other end users in industrial and other IoT-related communities delves into the importance of different selection criteria when evaluating and selecting various system components. VDC’s 2017 survey of the industrial automation community―which had over 225 respondents, more than 100 of which reported using position sensing instrumentation―asked respondents to assess the importance of various product characteristics when selecting position sensors.

According to these responses, decision-makers view accuracy and reliability as the most critical selection criteria for position sensors. Overall cost and overall value (cost vs. quality), while both ranking among the five most important characteristics, are significantly less influential. The supplier’s name or brand is significantly less important.

(Percent of Respondents)

Position sensors themselves rarely deliver significant value-differentiation to the services industrial organizations provide or the products they produce. In most applications, the true value of position sensors is in ensuring the precise, consistent, and safe operation of industrial systems. Survey results indicate that decision-makers will tolerate higher initial purchase prices in exchange for confidence that the position sensors will function correctly for a long time and thereby minimize operational expenses from poorly operating systems, damaged equipment, or the loss of productivity during sensor replacement. Product information and marketing materials should consequently stress these factors and highlight any assurances, such as warranties, of operational precision and product longevity. Suppliers should likewise focus their product development budgets to facilitate incremental improvements in these areas.

Several factors, such as SIL ratings, intrinsically safe design, and non-contact operation less frequently influence position sensor purchasing decisions for the overall market. However, for certain specialized applications such as mining, these characteristics are absolute necessities. Sensor suppliers aiming to provide a comprehensive sensor portfolio should consider investing developmental budget to organically expand their product catalog or consider M&A or white-labeling agreements to offer sensors with these capabilities. Sensor connectivity and SIL ratings are factors that VDC believes will grow in importance across the forecast period of this report. These capabilities are areas in which suppliers of a technologically mature product can dedicate scarce resources.

More insight

How will the expectations and requirements of engineers evolve over the next few years? Which suppliers are in the best strategic position for market growth? VDC’s latest report, 2018 Global Market for Proximity Sensors, Photoelectric Sensors, and Limit Switches

explains.

Research for the next two reports in this series―covering the global markets for linear displacement sensors and rotary displacement sensors, respectively―is currently underway.

Please contact us for more information.