Enterprise Mobility & the Connected Worker Blog

Are Robots Really Taking Over? How the Rise of Robotics is Transforming Warehouse Operations

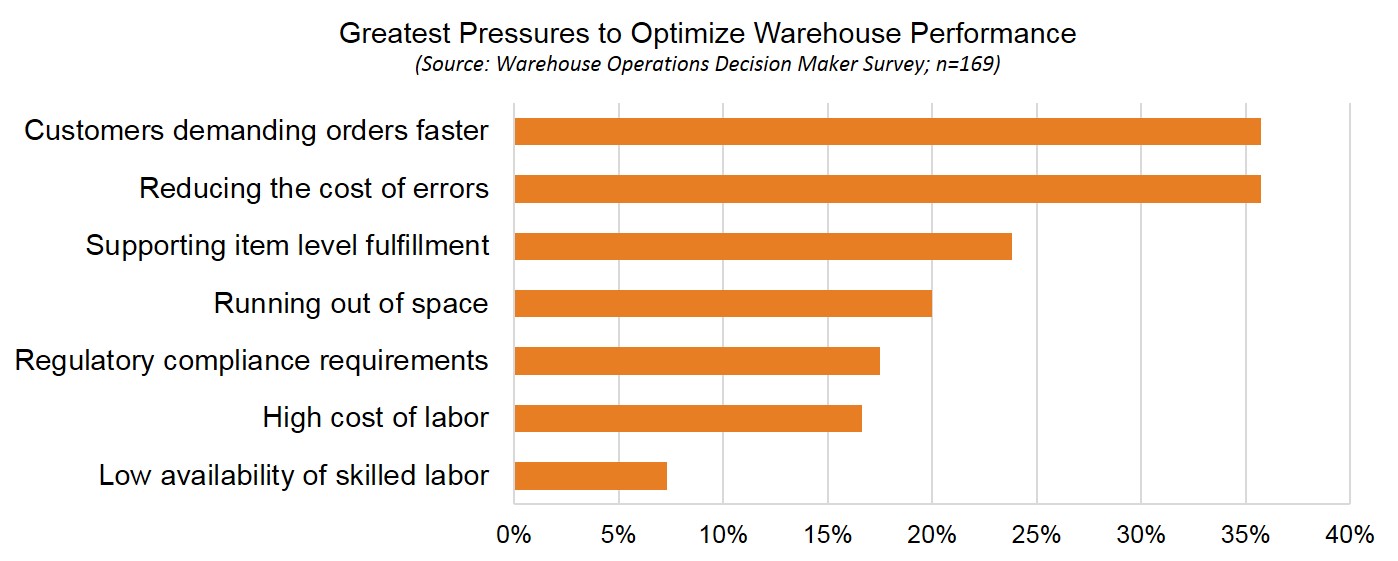

Everyone is talking about the rise of e-commerce, and what it means for traditional brick-and-mortar businesses across a wide array of industries; however, it also has meaning for warehouses and distribution centers, and, more specifically, how organizations are designing warehouses and distribution centers to efficiently fulfill this growing swell of e-commerce orders. Keeping up with demand – especially during peak holiday seasons – has proven itself a massive challenge. The warehousing industry is roughly a $31 billion industry, when you include warehousing, distribution centers, storage and e-commerce fulfillment, employing more than 650,000 people each year in the U.S alone (globeconfreight.com). This does not include temporary seasonal workers, which numbered 120,000 during the 2016 holiday shopping season for e-commerce superpower, Amazon. Managing the growing volumes of e-commerce orders, the demands of item level fulfillment and the challenges of on-boarding temporary workers are top of mind concerns for warehouse operations professionals, as confirmed by recent research conducted by VDC Research.

The inefficiency in daily workflows has created room for technology startups and innovators to unveil the ways that organizations can utilize robotics and automated vehicles in their everyday business processes. Although automation and some level of robotics is not new to warehouse operations, recent advances impacting a number of enabling technologies is fundamentally accelerating the opportunity. Ready access to sophisticated vision technologies for more accurate guidance and enhanced embedded intelligence and sensing solutions are ushering in a new wave of automation and robotics solutions for material management use cases.

Early to recognize this opportunity, Amazon snapped up Massachusetts-based robotics company Kiva Systems, back in 2012. Through this transaction, Amazon effectively took Kiva’s innovative technology off the market as Amazon viewed it a critical competitive advantage to its operations. Kiva’s robots were specifically designed to streamline and simplify the fulfillment process in warehouses and distribution centers, allowing organizations to better keep up with the constant demands of e-commerce. Today Amazon has more than 80,000 automated robots in use across its warehouses globally.

Many warehouses around the country have already employed the use of small robots that can work alongside humans, making the fulfillment process more efficient. Companies like 6River and Locus (both MA based organizations) have created small, roaming robots that move through the aisles of a warehouse carrying packages up to 10-15 lbs., dropping them into shipping piles. A human stands beside the conveyer belt and selects specific items for shipping and places it on the robot, which carries it away to the proper location for shipping, based on a barcode on the item. Other companies such as Vecna have developed larger robots that more closely resemble automated vehicles or forklifts. These robots are designed to lift pallets and stacks of merchandise, helping to move large quantities of items around the warehouse. Yet other groups like RightHand in Cambridge, MA, are focused on the next generation of robotics in daily business use; creating a robot that can identify a specific item out of a pile for picking and packing, without the assistance of a human. Each of these organizations are focusing on the market for robots specifically in the fulfillment process, and while there is room for expansion in how much of this process a robot is capable of sans human intervention, there are also speculations for other ways robotics will change the landscape of warehousing and e-commerce. Of particular interest is automated item-level picking in unstructured environments, a workflow that has been especially challenging to automate.

So what does this mean for those people who work in warehouses and distribution centers? For now, not very much as many of the use cases we are witnessing position robots as ‘companions’ to labor, working side by side. Rather than running all over the fulfillment center to pick and pack an item, humans can now take advantage of robotic technology to help streamline the monotonous process. This will allow companies to fulfill more orders per day, and keep up with the demands of their customers. As these technologies continue to develop, however, it is hard to envision a scenario in the mid to long term that does not include some level of contraction of the overall warehouse workforce.

View the 2017 Enterprise Mobility & Connected Devices Research Outline to learn more.