Industrial Automation & Sensors Blog

Five Industrial Automation Trends to Watch in 2017

From Big Data to industrial robots, here are five trends we’ll be watching in 2017:

Emphasis on data-driven manufacturing

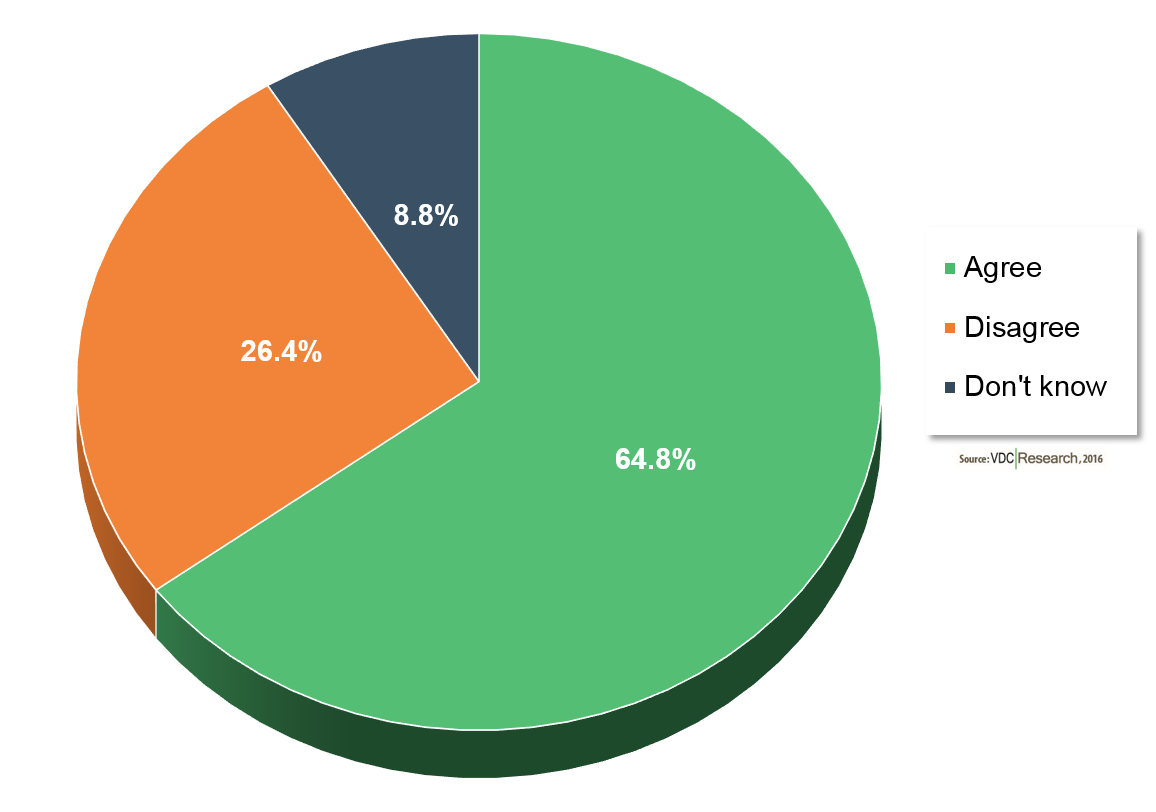

Manufacturers’ ability to effectively harness the power of Big Data to maximize operations will be the single biggest Industrial Internet of Things (IIoT) trend to watch in 2017.Though nearly two-thirds of respondents within the Industrial Automation segment of VDC’s Voice of the IoT Engineer survey reported their organization’s customers are not currently realizing the full benefits of IoT connectivity (see Exhibit 1), this will be a major emphasis this year. Expect significant investments in data-driven manufacturing initiatives such as predictive maintenance and real-time production monitoring as manufacturers continue to leverage advancements in industrial connectivity, as well as in sensing capabilities, data acquisition systems, and other related technologies.

Exhibit 1: The Full Benefits of IoT Connectivity Remain Largely Unrealized

Evolution of software functionality

The key to utilizing data is the ability to effectively create outputs that can inform critical decisions. In industrial settings, this often means that data must be accessed by non-technical users with limited experience in data manipulation and analysis. Similarly, the expanding degree of customization and programmability in many industrial systems increasingly puts non-technically-inclined users in charge of sophisticated software systems they may have no desire to operate. Look for industrial software vendors to focus on simplifying user interfaces, improving ease-of-use, and integrating self-service as their customers look to get value out of their data as quickly and efficiently as possible.

Rise of intelligent, industrial robots

One of the most intriguing developments in the age of Industry 4.0 is the increasing presence of intelligent robotics on factory floors. While robots have been used in manufacturing for decades, the continued development of robotics technologies has dramatically broadened the potential use cases for smart, industrial robots. Combined with unprecedented levels of connectivity and communication in industrial environments, the possibilities appear endless. In 2017, continued advancements in artificial intelligence will further accelerate this trend, however many manufacturers may still bide their time as they seek to understand what type of intelligent robotics application will generate the most value for their organization.

Prioritization of green initiatives

Responsible, environmentally-conscious manufacturing practices will be paramount in 2017 as manufacturers hold themselves accountable to investors, employees, and customers worldwide. In the United States, the importance of this theme is underscored by the Energy Department’s creation of the REMADE (Reducing Embodied-energy and Decreasing Emissions) Institute in early January. This organization – led by the Sustainable Manufacturing Innovation Alliance and backed by federal funds and cost-share commitments from more than 100 partners including Dell and John Deere – will focus on lowering the barriers to sustainable manufacturing with the goal of attaining a 50% improvement in energy efficiency in the next ten years. Accordingly, expect manufacturing organizations to begin leveraging technologies that enable the responsible and effective reuse of manufacturing materials.

The call for security

Though most manufacturers are still in the early stages of leveraging the IIoT, cyber criminals have already demonstrated a propensity for exploiting vulnerabilities. To protect their IIoT investments, devices, and data, manufacturers must ensure their industrial systems are protected from end to end. Fortunately, the relative infancy of this market will allow many manufacturers to incorporate a variety of security strategies – device security, communications security, security monitoring, and other security services – from the beginning. Look for security solution vendors and industrial automation thought leaders to push industrial security strategy and best practices through a variety of targeted solutions, services, and education.