IoT & Embedded Technology Blog

Key IoT & Embedded Takeaways from Intel IFS Direct 2024

by Dan Mandell | 2/23/2024

The first Intel Foundry Direct Connect event took place this week and VDC Research was on hand to learn about the biggest implications to the IoT and embedded market. There were several key announcements made during the event on February 21st including the launch of Intel Foundry – Intel’s System Foundry approach to enable full-stack optimization for the AI era. Bleeding-edge process technologies are typically most focused on datacenter/hyperscalers, HPC, digital models, and enterprise AI applications. However, there is certainly still significant applicability in some IoT and embedded systems as well, particularly in some A&D, autonomous vehicle, scientific/energy modeling, and other demanding environments. Intel’s foundry efforts will have massive ripple effects on the market at large as a leading device supplier/IDM.

Among the biggest implications for the IoT and embedded space is Intel Foundry’s commitment to accelerate time to design and the development of heterogeneous computing solutions. The collaboration with Arm on emerging business initiatives for Arm-based system-on-chips is a prime example of the dramatic coopetition strategies necessary in the industry. Arm and Intel, still competitors in the semiconductor device space, will generate significant value working together to support startups in developing Arm-based technology with access to key IP, manufacturing support, and financial assistance to jumpstart innovation. Intel’s commitment was also on display at the keynote as MediaTek and Broadcom were both on hand to discuss how their partnerships with the foundry are helping them scale and innovate with new packaging technologies and components (e.g., substrate interconnects) while also helping diversify their supply chain. This messaging was reinforced further with key demo partners on hand from Andes Technology, BrainChip, and SiFive, which are all looking to leverage Intel Foundry’s capabilities to deliver their own silicon innovations.

This brings us to another significant arm of the Intel System Foundry strategy: delivering a resilient and sustainable supply chain. A staggering amount of silicon production (~80%) takes place in Asia, which is a far cry from how the landscape was a few decades ago when 40% of semiconductor chips were manufactured in the Americas. The rapid emergence of AI and the importance of silicon for modern vehicles, life-saving medical devices, and other key systems for advancing society have driven dramatic new domestic investments and national technology initiatives. The U.S. CHIPS Act is a key component to “bringing silicon back to silicon valley” and getting the flywheel moving to accelerate research and development and create new high-paying jobs for America and its “siliconomy.” Intel is the biggest champion for the U.S. in achieving its goals for decreasing national dependency on other countries for semiconductors and maintaining a competitive edge in the field of AI.

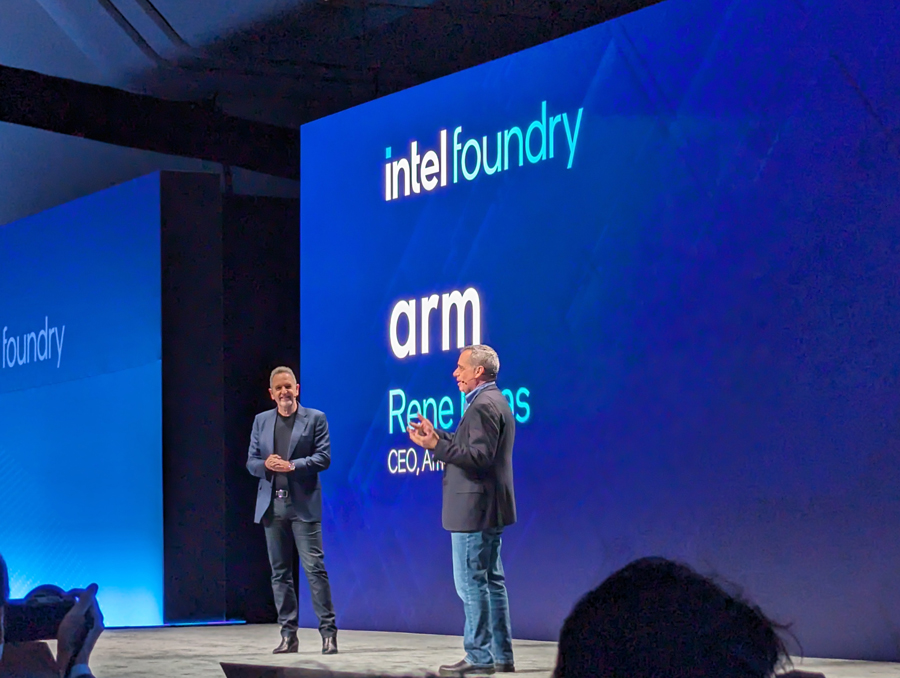

Arm CEO, Rene Haas, is introduced to discuss Arm’s role with Intel Foundry at the Intel Foundry Direct Connect Event (Source: @DanMandell on X)

Building a diverse ecosystem of IP and EDA partnerships continues to be a top priority for Intel Foundry to accelerate chip designs. At the event, Intel repeatedly wrang the importance of these partners, such as Ansys, Cadence, Siemens, Synopsys, in tool qualification and IP readiness across its various node families. EDA solutions are essential for accelerating development and delivery of advanced packaging solutions in the age of “SysMoore” or the rapidly growing systemic complexity of computing solutions. Access to IP is also a critical productivity enhancer in the industry and addressing SysMoore. Combining the capabilities of EDA for enablement, reference flows, and certification with key IP allows semiconductor makers to adapt their designs to new processor nodes while optimizing both digital and analog workflows.

Intel Foundry has advanced its strategy, offerings, and integrations dramatically within a few short years and has a rich roadmap ahead for the development of cutting-edge silicon. Its impact will be dramatic for external customers (i.e., designs based on Arm, RISC-V, other architectures, and the integration of components from other foundries). At the same time, as an internal customer, Intel gains the shared benefits of establishing a more resilient supply chain for itself with expanded lifecycle support and product availability. The company’s innovations in chiplet technology will also parlay into the IoT and embedded space as demand for heterogeneous compute continues beyond traditional system-on-chip architectures. Creating a global foundry business with high scalability takes considerable time, resources, and capital, but Intel is making huge advancements with Intel Foundry to position itself as a critical technology enabler and provider for the computing industry at large.