Enterprise Mobility & the Connected Worker Blog

Welcome to the Industrial Metaverse: XR Powerhouse Roundtable Discussion – Key Implications for enterprise mobility

On May 18, RealWear hosted Welcome to the Industrial Metaverse: XR Powerhouse Roundtable Discussion with Andrew Chrostowski (Board Chair & CEO| RealWear, Inc.), Indranil Sircar (CTO, Manufacturing Industry | Microsoft), Brain Vogelsang (Sr. Director, Product Management – AR | Qualcomm), and John Fan (Board Chair & CEO | Kopin). The discussion explored the benefits, challenges, technology requirements, and potential use cases of the industrial metaverse. Benefits are expected in productivity, access to data, and worker experience, but the panel anticipates the most impactful changes will relate to worker safety. For this technological revolution to occur and place safety at the forefront, the worker and physical world will always take priority over the digital world. Panelists stressed that, while much of the technology required for a metaverse experience in the enterprise already exists, there are still gaps which will be addressed in stages over the coming years.

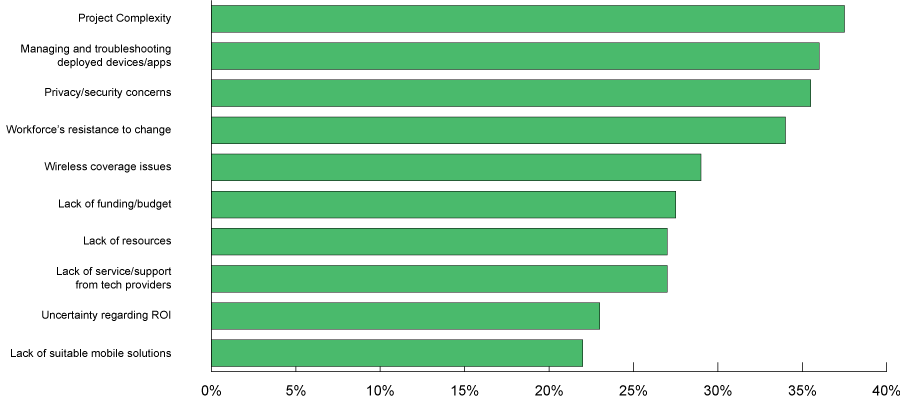

While there is much hype surrounding the metaverse and its assumed success in enterprise applications, there are still many barriers preventing its adoption and success. In fact, metaverse adoption is vulnerable to at least the top seven barriers to implementing mobile solutions in manufacturing environments (Exhibit 1). One glaring challenge will be lackluster digital transformations in industrial settings. While some organizations are on the cutting edge in terms of IT infrastructure, there are many which have yet to adopt cloud or edge computing solutions – some still use pen & paper for many processes. Connectivity and security concerns also present a barrier to metaverse adoption, but private 5G networks are an attractive solution to these issues. Funding and ROI are always key to adoption rates in enterprise settings, but the workforce’s resistance to new technology could impair the metaverse’s prospects more than anything. Considering the myriad benefits and challenges of the industrial metaverse led us to consider the implications of its potential success on enterprise mobility – specifically on innovation, network connectivity, and connected workers themselves.

Exhibit 1: Leading barriers to deploying mobile solutions in manufacturing operations

Innovation & Staged Metaverse Implementation The core of the metaverse is bringing physical and digital environments together. Assisted reality is currently the technology in use which is closest to doing this, but much R&D funding is funneling into technologies intended to enable it at a more advanced level. Industrial metaverse implementation will occur in stages as the technological innovations occur and eventually become affordable. While some of the necessary tech, including LIDAR (Light Detection and Ranging), is metaverse-ready now, other tech – especially wearable hardware – will need to advance rapidly to enable evolution in extended reality. Operators in manufacturing environments often wear hardhats with which optical wearable devices will have to integrate seamlessly and comfortably. The panel agreed that the digital world will always be secondary to the real world in industrial environments, with Kopin CEO John Fan positing that AR optics will likely reside side-by-side with reality, describing the relationship of physical to digital as similar to that of a the windshield (physical) and instrument cluster (digital) in a vehicle.

The Implications of 5G/Private 5G on the Industrial Metaverse A major step in reaching the metaverse in industrial settings is ensuring digital transformation and connecting everything in the enterprise, from machinery and equipment to sensors, vehicles and people. As more tools, technologies and applications are introduced, the complexity of the industrial environment grows. Traditional Wi-Fi networks are not equipped to handle these new complex use cases and increased network densification. Although the evolution of Wi-Fi will still be necessary to the enterprise for communication and the connectivity of many mobile devices, use cases that involve higher uplink speeds and lower latency for automation and faster data processing at the edge require cellular/5G technologies. Private 5G will enable industrial settings to be fully connected and inherently more [digitally] secure. The panel encouraged that workers will be more productive when they have access to more data and faster processing capabilities, which can be enabled by the integration of private 5G networks in industrial operations. In VDC Research’s 2021 Enterprise Buyer Behavior Guide, 35.2% of decision-makers in manufacturing indicated that their devices would connect via 5G in the next 12 to 24 months. Additionally, 14.8% indicated their devices would connect via Private 5G in that same time period. .

Truly Connected Workers The panel emphasized that, as the industrial metaverse evolves and grows, the definition of a connected worker will change. Any worker using legacy devices and not in the metaverse will be at a disadvantage; they will no longer be a connected worker. Meanwhile those who are utilizing the metaverse will more so be within the digital world than connected to it. Workers simultaneously within the digital and physical worlds will experience improved safety and productivity while enjoying instant access to data and augmented reality visuals. Though there is much uncertainty surrounding the metaverse and how it will ultimately compare to the hysteria around it, it seems that if it becomes even one-half as transformational as its proponents expect, the way in which mobile workers perform their jobs will fundamentally be changed.