Enterprise Mobility & the Connected Worker Blog

Delivery Robots Help Alleviate Frontline Worker Pressures

.png)

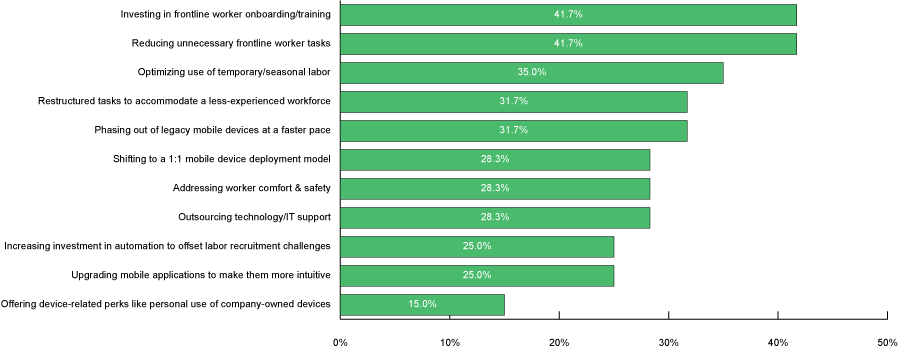

| Frontline labor challenges have persisted in 2023, and industries like transportation, deliveries, logistics, food service, and manufacturing continue to face record turnovers. Enterprises have adopted a multitude of strategies to expedite training, retain workers, and increase a sense of value as job satisfaction drops. While some companies are considering semi and full automation of their operations, others are seeking out ways to retain their workers while identifying, isolating, and eliminating less-popular tasks. According to VDC’s 2022 Buyer Behavior Guide, over 41% of retailers identified reducing unnecessary frontline worker tasks as a top priority to address labor challenges. |

Innovative startups have launched new autonomous delivery robots (ADRs) to meet these needs and show how human and robot workers might collaborate. The Ottobot, an electric, autonomous delivery robot, can perform deliveries for food and e-commerce orders. Created by Ottonomy, the Ottobot specializes in hyperlocal delivery, which can include last mile (within 1-1.5 miles), in-facility delivery at airports and resorts, and curbside delivery. Standard Ottobots have 2 compartments. Compartments can also be adapted to accommodate the cold chain and require security codes before releasing a delivery. The modular capabilities of the robot platform enable it to complete multiple deliveries in a single trip, increasing its delivery throughput and overall efficiency. With a five-hour battery life, Ottobots can park themselves at charging stations, allowing battery swapping to increase their operational hours.

What are the top three initiatives taken by your organization to address frontline labor challenges?

2022 VDC Buyer Behavior Guide, n=60

The Ottobots, launched in 2022, have run successful trials in the airport environment and are now operational in Cincinnati, Pittsburgh, and Rome airports. Ottonomy is currently piloting last-mile delivery for companies in the US, Spain, Norway, and the Middle East. With customizable compartments, the Ottobots can adapt to a range of applications and environments, including retail, food service, and logistics.

The mobile workforce underwent dramatic changes during the COVID-19 pandemic. Social distancing and worker shortages led service staff to be repurposed in higher value roles – with these roles both paying higher wages and offering a higher tier of skills, workers are unlikely to return to their past workflows. At the delivery end, consumers are unhappy about higher delivery fees resulting from a shrinking labor pool for deliveries, which has led to an increase in hourly wages of up to 100% in some cities. AI-enabled robots like the Ottobot isolate lower-value workflows like last mile, curbside, quick service delivery, in turn freeing mobile workers to focus on higher-value, more rewarding tasks like inventory management and customer service. By allocating delivery tasks to an Ottobot, enterprises have been proven to spend 50% less on delivery workflows than they would otherwise have done.

Ottobot is one of a new group of ADRs that seek to address unpopular, less-valued mobile workflows, and elevate workers to perform tasks that are more fulfilling and valuable. The cohort also offers financial and environmental benefits by cutting fuel costs, which are much higher when deliveries are made using cars. Peers in the ADR space, which include Starship, Kiwibot, and Coco, can be seen performing assisted teleoperated deliveries on college campuses and conducting short-range deliveries for local businesses. These added-value tasks offer both financial benefits to the companies using them, and elevated roles for workers who may attain a higher pay grade as a result.

Mobile worker preferences have become a top factor in enterprise mobility investment decisions. To learn more about how mobility investments are changing across industries, read VDC’s 2022 Buyer Behavior Guide.