Industrial Automation & Sensors Blog

Welcome to Kryvorizhstal

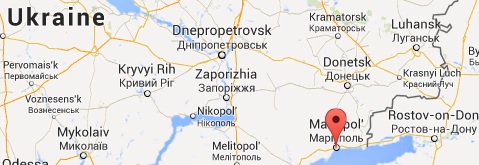

Kryvorizhstal (MT) is the largest steel producer in the Ukraine just ahead of the Illich Steel and Iron Works in Mariupol, 15 miles west of the contested Russian border. This area is also close to Donetsk which has been in the news recently. These two gigantic and fully integrated metallurgical enterprises are critical to the European and Russian economies as well as the global steel market. Each has the equivalent capacity to produce the steel for 100 aircraft carriers and both are at severe risk of shutting down or being commandeered.

The Mariupol facility is owned by the single richest man in the Ukraine and the structures lie next to ample deposits of coal and coke as well as a seaport for iron ore shipments. Employing around 30,000, the steelworks runs more like a city than a factory. Workers are equipped with the standard accoutrement; wrenches, measurement devices, radios and to add a Russian twist, guns. The perimeter is also heavily reinforced with light artillery. The facilities are in constant alert as fighting between Ukrainian soldiers and Pro-Russian militants rages just beyond the outer perimeter.

Both plants have seen a sharp slowdown in business as incoming shipments of raw materials has been an issue. An unfortunate occurrence, as iron ore shipments are setting records in 2014. This has created an opportunity for Chinese steelworks who have taken up the slack within the market. This can be seen in the most recent Chinese PMI, released yesterday, which many economists considered a modest but surprising and unexpected uptick in the reading.

While economists scramble, the analysts weigh in. Both plants have begun new plans for expansive overhauls of their existing processes. Kryvorizhstal and Illich are looking to retrofit existing assets with the latest automation and monitoring equipment. Several suppliers could benefit here, including SICK with their Bulkscan LMS511. The system is used to scan material as it travels along a conveyer, perfect for measuring material as it is dumped into the blast furnaces. Blast furnaces also need infrared temperature sensors during the smelting process. Position sensor vendors such as IFM may also have success with their automated crane solutions. Both Kryvorizhstal and Illich have extensive rosters of steel rolling equipment and machine building divisions.

The opportunity for automation within the Metals & Mining sector is immense. This sector will generate some of the first fully automated vehicles in the form of dump trucks used to transport ore. The operations are already automated to the point that proprietors can dial up or decrease the amount of ore produced as demand fluctuates. Automation suppliers should ignore the overall growth rates of the mining sector which have created the picture that the sector is stagnant. On the contrary, automation innovation within the Metals & Mining sector has been strong.

As the Ukrainian conflict rages on, so too will the global economy. Record production of iron ore and steel bodes well for growth, however the Kyrvorizhstal and Illich facilities may not fully participate until they can receive unfettered shipments. This may present an opportunity for automation suppliers as un-commissioned equipment can be easily upgraded during the down-time. The slack has already been absorbed by the Chinese steel mills which are also upgrading to the latest automation technology. Suppliers with a solid understanding of these market drivers and an intrepid sales force should target these facilities and steel plants worldwide.